Page 22 - respond-cop29

P. 22

Change for a more sustainable future

Pamela Phua, Global Product Management Director,

Innovation & Sustainability, Decorative Paints, AkzoNobel

Climate change stands as one of the most pressing As a company committed to sustainable development,

challenges humanity faces today. The year 2023 and AkzoNobel has prioritized innovation to provide solutions

the first half of 2024 saw numerous record-breaking that help combat global climate change. Built on a solid

temperatures and extreme weather events worldwide. foundation of passion and dedication, the AkzoNobel team

January 2024 marked the hottest January on record, has relentlessly pushed boundaries to create new, high-

with an average sea surface temperature of 20.97°C, quality, aesthetically pleasing, safe and more sustainable

surpassing the previous record set in 2016. surface solutions.

These disruptions to nature directly impact our In 2023, AkzoNobel embarked on comprehensive

environment, ecosystems, human lives and production improvements and innovations driven by a shared ambition:

processes, etc., ultimately affecting global development to paint the future and collaboratively build a vibrant,

and security. Addressing climate change has thus become colourful and more sustainable world for future generations.

an urgent imperative for every nation and its people.

DUAL GOALS ON SURFACES

As a reputable global provider of surface products and is a solid form of resin) one extracted from rapeseed and

solutions, AkzoNobel's product range spans various one from pine rosin, meeting all colour and functional

economic sectors, including industry, production, services requirements, including UV protection, air cooling,

and residential use. AkzoNobel's innovations significantly temperature regulation and scratch resistance.

influence industry transformations and the lives of

customers, as demonstrated by the following achievements: Pursuing a philosophy of perfect surfaces that are not

only beautiful but also meet quality, impact, efficiency and

In the Beverage Industry: sustainability criteria, AkzoNobel sets high expectations

AkzoNobel introduced Aqualure G1 50 and Accelstyle, the for its R&D team. This team is tasked with delivering

new generation of coatings technology compliant with FDA digital solutions that streamline processes and increase

and EU regulations, enabling beverage can manufacturers to profitability, helping auto repair shops work smarter and

offer products with surfaces free from bisphenols, styrene more sustainably. Refinish+ is one of the outcomes of this

and PFAS. The new products allow manufacturers to switch effort. This is a comprehensive set of solutions from Sikkens

to coatings that do not contain harmful substances, while Vehicle Refinishes for repairing the entire paint layer on

maintaining commercial viability. Additionally, AkzoNobel's vehicles, from restoring the original colour, reducing drying

bisphenol-free products reduce carbon emissions by up to time and volatile organic compounds (VOC) emissions, to

26% compared to previous epoxy-based products. It means, lowering carbon emissions on the vehicle body, etc.

with Accelstyle, AkzoNobel achieves the dual goals of

protecting users and minimizing environmental impact. In the Powder Coatings Industry:

AkzoNobel’s approach to sustainable development

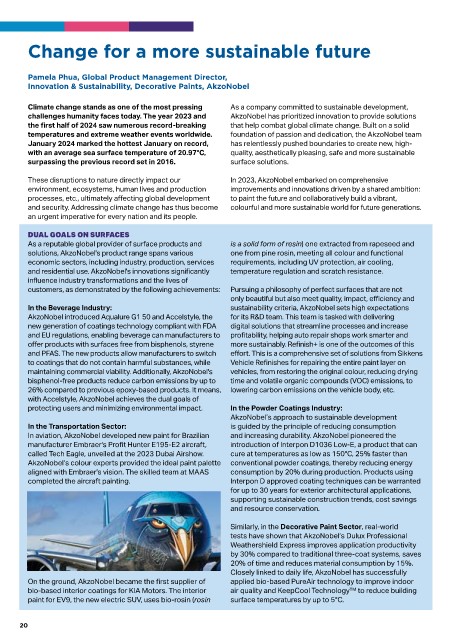

In the Transportation Sector: is guided by the principle of reducing consumption

In aviation, AkzoNobel developed new paint for Brazilian and increasing durability. AkzoNobel pioneered the

manufacturer Embraer's Profit Hunter E195-E2 aircraft, introduction of Interpon D1036 Low-E, a product that can

called Tech Eagle, unveiled at the 2023 Dubai Airshow. cure at temperatures as low as 150°C, 25% faster than

AkzoNobel’s colour experts provided the ideal paint palette conventional powder coatings, thereby reducing energy

aligned with Embraer's vision. The skilled team at MAAS consumption by 20% during production. Products using

completed the aircraft painting. Interpon D approved coating techniques can be warranted

for up to 30 years for exterior architectural applications,

supporting sustainable construction trends, cost savings

and resource conservation.

Similarly, in the Decorative Paint Sector, real-world

tests have shown that AkzoNobel’s Dulux Professional

Weathershield Express improves application productivity

by 30% compared to traditional three-coat systems, saves

20% of time and reduces material consumption by 15%.

Closely linked to daily life, AkzoNobel has successfully

On the ground, AkzoNobel became the first supplier of applied bio-based PureAir technology to improve indoor

bio-based interior coatings for KIA Motors. The interior air quality and KeepCool Technology™ to reduce building

paint for EV9, the new electric SUV, uses bio-rosin (rosin surface temperatures by up to 5°C.

20